Loading

Why a 3D Scanner Is Needed in Large Casting’s 3D Inspection?

Common methods for casting’s 3D inspection

To meet casting part dimensional requirements such as tolerances, a metal casting facility can check the dimensional accuracy of parts manually or with coordinate measuring machine (CMM).

Manual inspection refers to traditional measuring methods such as ruler checking or marking tool-checking, which are inaccurate, time-consuming and laborious while been used to complete the dimension or size control.

CMM has improved the speed and accuracy of measuring casting dimensions, and computerization has made it repetitive and able to be used as a statistical tool. But it’s not applicable for big and heavy casting parts because of its high cost and low efficiency. It’s more popular to use a 3D scanner for large casting quality inspection.

Advantages of a 3D scanner in large casting inspection

Impressive Portability:

–It can change its angle flexibly to scan different surfaces.

–It is suitable for detecting narrow spaces and the inner feature of a large casting.

–It can be used at the factory itself and also for measurements at the customer’s site.

Excellent Stability: it is insensitive to temperature & humidity change in shop-floor environments and ideal to measure parts that cannot be moved to a granite or cast-iron table.

Quick Start: little preparation is needed while other scanning solutions need to apply a spray or realize rigid and complex setups beforehand.

Easy-to-use: it only takes half an hour for a beginner to master the basic skills.

High speed and accuracy: with the help of a 3D scanner, the 3D inspection of a large casting can be completed in hours. And the accuracy and resolution can both be up to 0.01mm.

ZG’s 3D solution for large casting inspection

Currently, for large and heavy castings’inspection, 3D scanning solution technology prevails internationally.

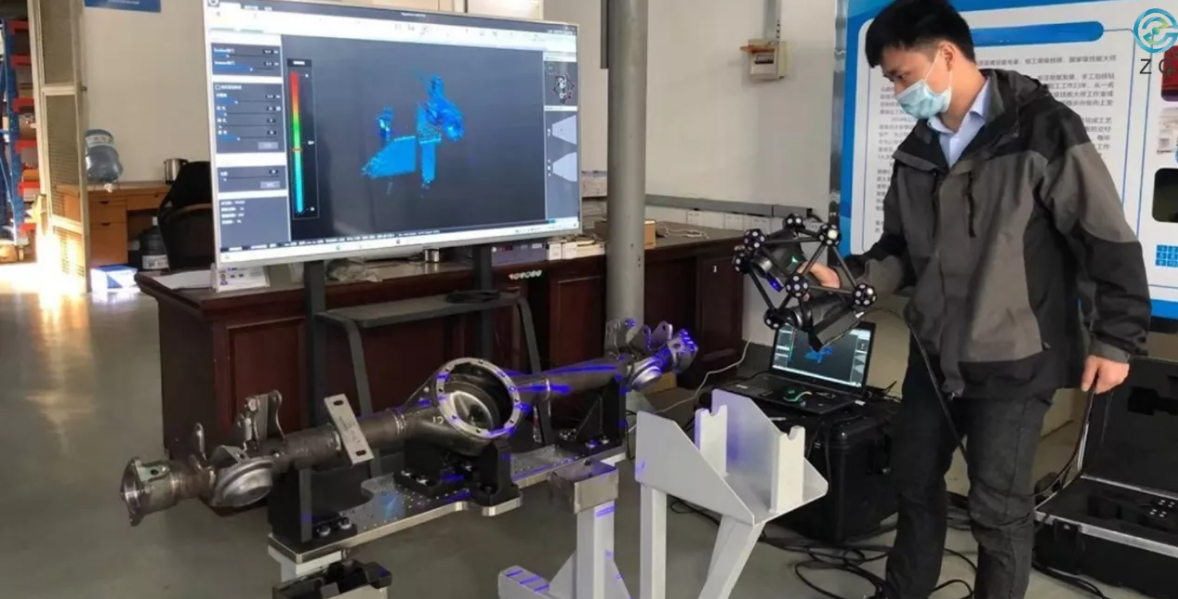

ZG’s HyperScan Plus is a 3D scanning solution composed of a portable 3D scanner and an optical tracker Z-Track that enables dynamic referencing, automatic alignment, and continuous monitoring of parameters.

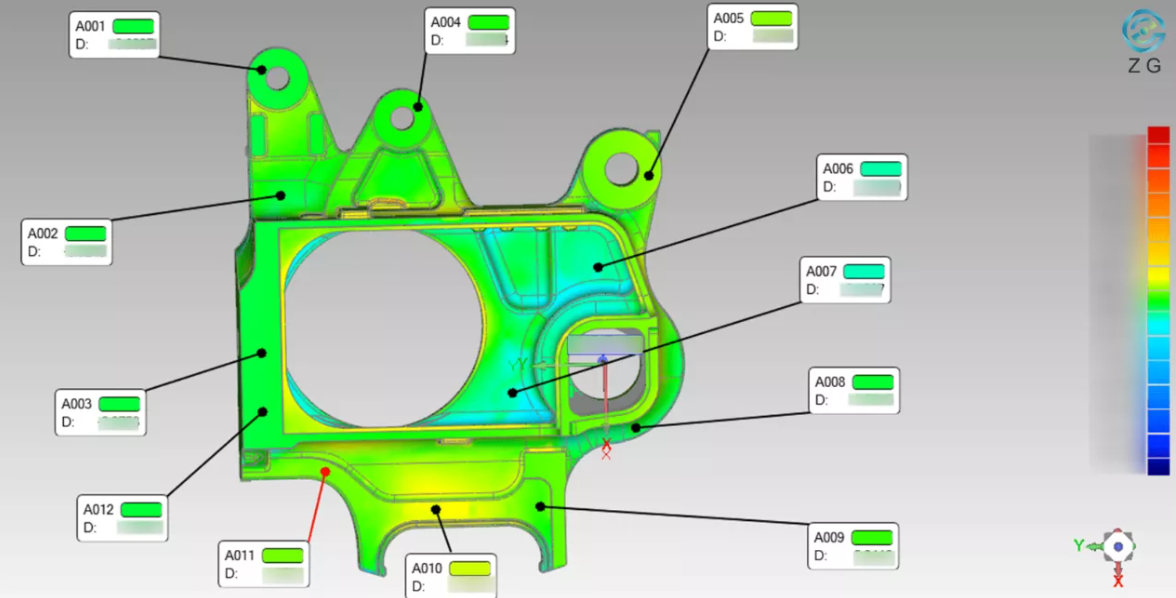

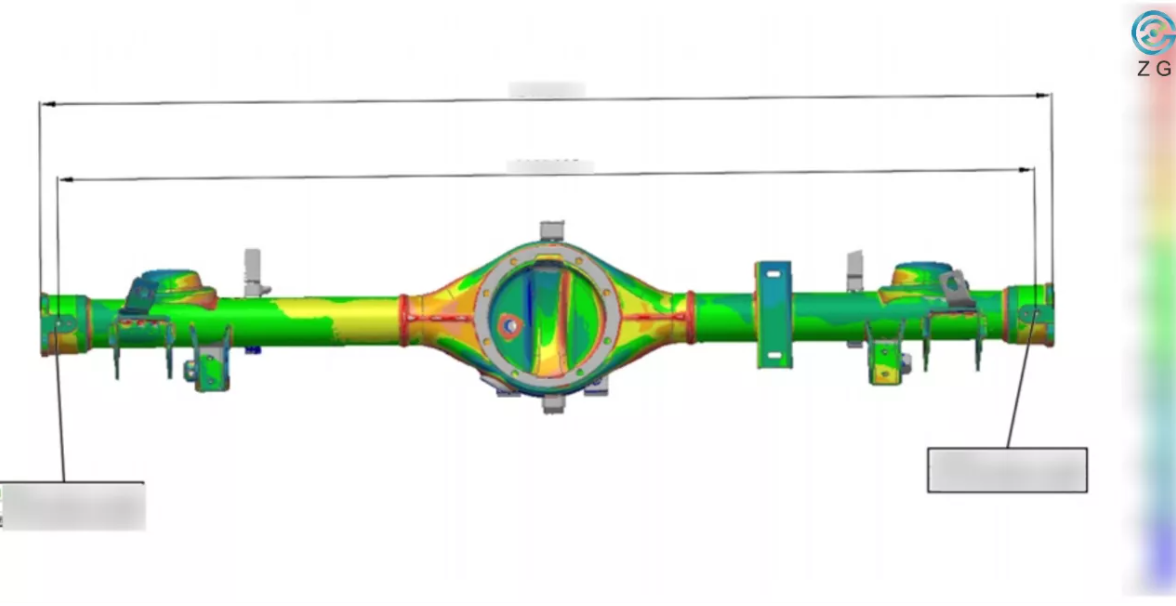

By applying HyperScan Plus, the point cloud data of the casting’s surface can be collected, then a high-precision 3D mesh data will be generated. By comparing the data with its CAD file, we can get the dimension deviation directly to evaluate if the casting is qualified or not.

Scanning Process 2

ZG’s portable 3D scanning solutions offer significantly better performance when compared to traditional methods, even on the shop floor. Thanks to their portability and insensitivity to the typical working conditions found on the shop floor (e.g., movements, installations and vibrations). ZG’s solutions are highly efficient for measuring objects that are difficult to move. They are perfect for quality control, measurement and reverse engineering.

Why ZG is selected by customers

Time consuming and laborious, measurement and quality control were carried out using traditional manual measuring instruments in the past. ZG’s products were selected for its functionality and advantages: flexibility, portability, speed, ease of use, all with flexible configurations in any environment, improved quality, faster process and user-friendly software. The world of measurement is full of valid alternative solutions, but the versatility of ZG’s products was the main reason behind this choice.

You can use ZG’s 3D scanners not only in the measuring room, but also in other departments and at customer facilities. The use of the 3D scanners has significantly accelerated measurements and improved the level of quality. This allowed the company to meet customer demands that it could not handle previously.

In conclusion, ZG was selected because it perfectly responds to the fundamental concepts at the basis of the customer’s demands: high speed and precision. As a real pioneer in 3D scanning field, ZG will continue to innovate and move forward to serve customers better.